Safety-Wire Basics

Getting onto the racetrack requires some preparation. At high rpm, vibration tends to loosen nuts and bolts. The standard practice in all forms of high performance motorsports and racing is to safety wire any nut or bolt that may adversely affect the handling or performance of the vehicle. For participation in track days and the riderschool, you are not required to do extensive safety wiring but for your safety and your fellow riders, some basic safety wiring is required. It is not difficult and in most cases can be done in less than one hour. (Please see Bike Requirements for the different safety-wire requirements.)

You

will need the following items:

1) A high quality 16 inch drill bit,

cobalt or titanium is suggested. Cheap bits don't work well and you will

get frustrated using one!

2) Drill

3) Center punch. A ten penny nail

will work on aluminum but not hardened steel.

4) Hammer

5) Safety wire

6) Safety wire pliers or vise grips

Many times the nut or bolt can be drilled while in place. Of course, space and angles are always your limitation.

First, select the nut or bolt to be drilled. Then use the punch and hammer to dimple the nut or bolt to give the drill bit a place to start. Next drill through slowly. If you force the bit, it may snap off and you'll have to start all over. Also, as the bit begins to exit the nut or bolt do not force it through. Allow the bit to exit slowly on it's on. If you force the pace or put excessive pressure on this tiny bit, it may break. Be patient.

If you are going to drill through an engine flange or boss (built up exterior area), make sure it's a solid piece and you are not drilling into a fluid area. When in doubt, ask someone that can give you a definitive answer on your particular make and model of bike.

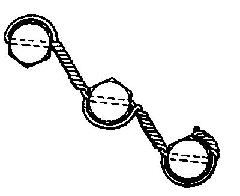

After the drilling is done, pull a piece of safety wire through the hole and double it in half. Take the two ends and begin to twist them together. Before you start twisting, try to measure the distance between the two drilled areas so you only twist the distance you need. If you do not have safety wire pliers, you can use vise grips or standard pliers to twist the wire together. Next pull one piece of wire through the second hole. Pull the wire tight in a clockwise direction so if the nut tries to loosen it will pull against itself.

Twist the two ends together and snip off the excess wire. Always put snipped off safety wire into a trash bin. If you drop it on the floor or ground, it will most likely end up in your tires or someone else's tires. As Murphy's Law dictates, you will never discover a flat in the pits, it only happens at 100mph+. So get in the habit of always putting sharp little pieces of safety wire into the trash can.

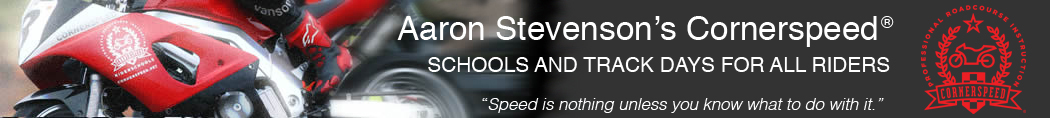

Spin-on type Oil Filter - how to safety wire it: First buy a hose clamp that will fit over your oil filter. Your local hardware store should have one that fits (usually a 3-3.25 inch works fine). Place the clamp over the filter (as close to the base as possible) so the excess strap of the clamp goes in a clockwise direction. Use one of the slotted ends of the strap to pull your safety wire through. Using a solid flange, mount or drill the end of a bolt and attach the safety wire as described above and you're done.

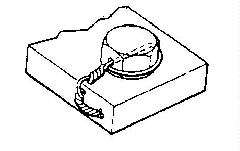

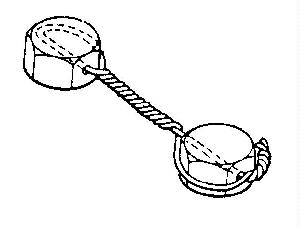

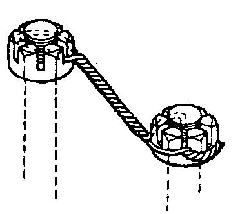

The following illustrations of safety wiring are provided courtesy of WERA.

The first image shows how to safety wire the oil filter. This is very typical of most manufacturers that use a spin-on oil filter. The second image shows how to safety wire the drain plug. Both pictures are from an SV650.

These images show how to safety wire the oil fill cap using a Cotter Pin (Safety Pin). You can use the pin to remove the safety wire and reuse it without having to cut the safety wire every time. The other option is not to use the pin and put the wire directly through the hole in the cap.

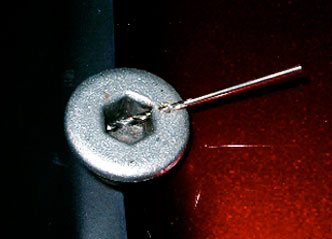

The first image shows how to safety wire a recessed drain plug with a recessed spin-on oil filter. Pictured here is a 998 Ducati. This is typical of BMWs and Ducatis that use flat plugs and recessed oil filters. Because there are no flanges or bosses nearby, the wire is pulled taught between the drain plug and oil filter. This way neither one can back out. Please note the RTV silicone used on the other two engine plugs. This isn't required, but a good idea. The second image shows how to drill a flat style drain plug - the drill bit was left in place to show the angle.